Building 50 Cedar Bath Trays (Goodland)

Starting with over 800 board feet of cedar wood, I worked from rough cut lumber to a finished product. Consistency, precision, and careful handling of the soft wood was crucial to produce a high volume of this bath tray for Goodland. Each unit was assembled, inspected, and packaged by me.

01. Rough cutting lumber near size.

02. Running each piece through the jointer.

03. Bringing each plank to thickness.

04. Using the panel saw to bring to width.

05. Adding 1/4” round overs to every edge.

06. Pre-drilling screw holes for hardware.

07. Adding threading for adjustable brass knob.

08. Assembling each unit with power drill.

09. 50 units finished and ready to be packaged.

10. Bathtrays are boxed and crate is built.

*Images Property of hellogoodland.com

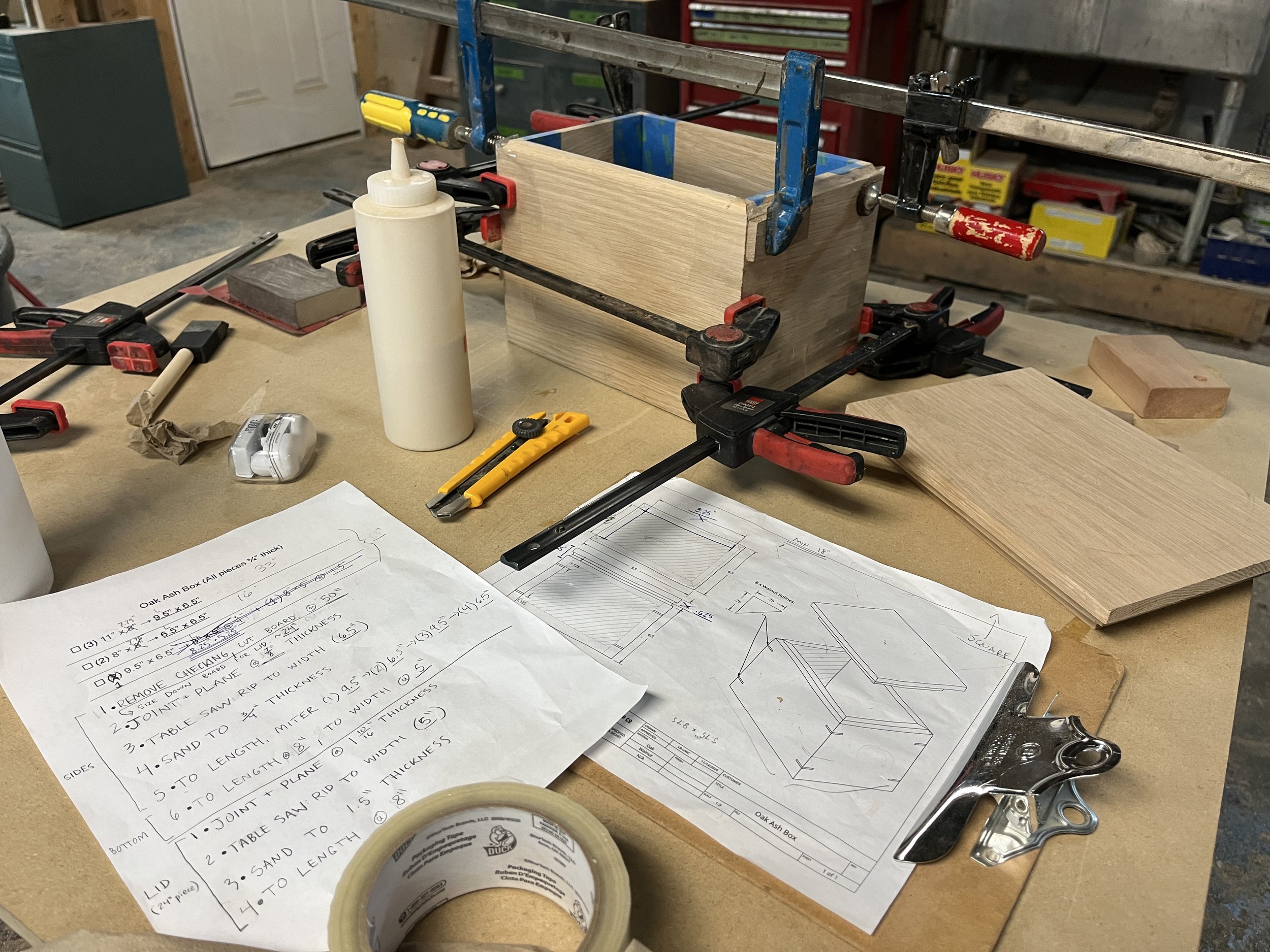

Ash Box

Built to hold that ashes of a loved one, this oak box with simple design with continuous grain around the box and walnut splines for contrast. The friction fit lid with thumb grooves were added for an easy to open and secure container.

Cutting Board

Made from off cuts of oak end grain, I used the dynamic grain of the wood to create a cutting board with movement and flow in its natural design.