Flex-Grinder

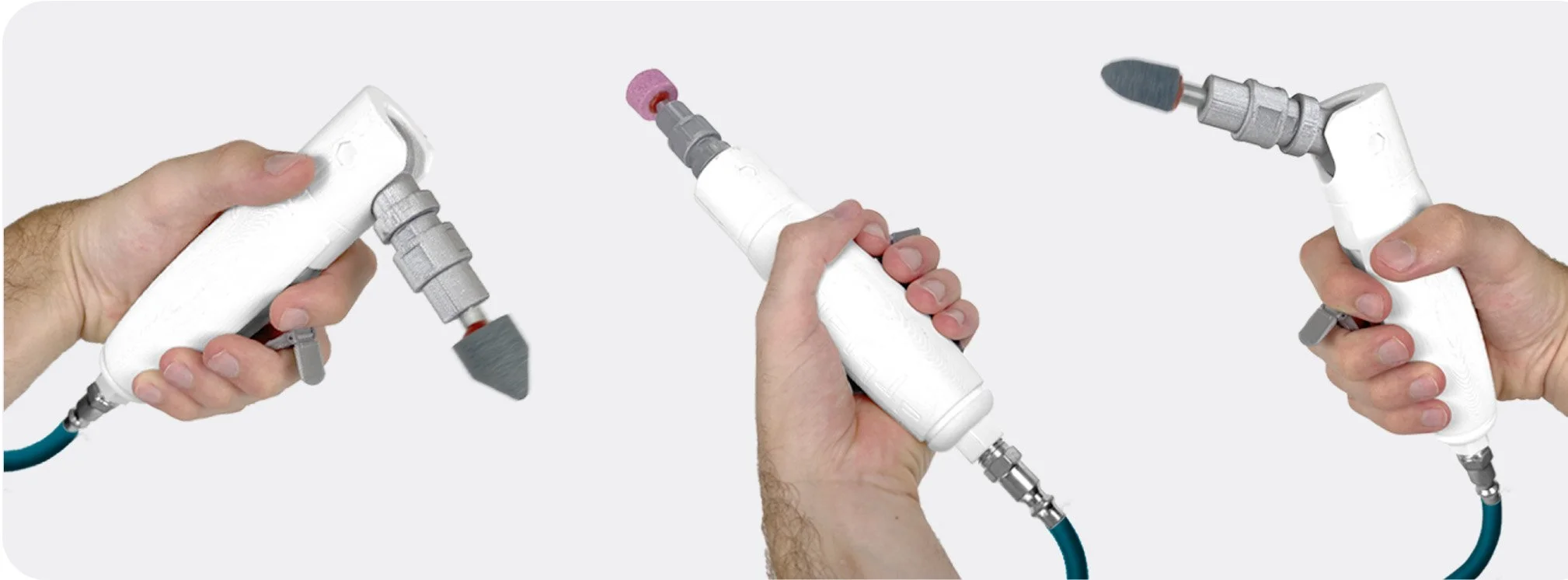

A die grinder able to manuver between 0° and 90°.

What is a die grinder?

The die grinder is a handheld rotary tool used for grinding, sanding, polishing, sharpening, and cutting surfaces or edges. It houses a small but powerful motor that is powered pneumatically or electronically. A pneumatic grinder consists of:

Adjustable Collet

Motor Housing

Air Flow Throttle

Valve

Steps of use:

01. Identify rough points.

02. Select grinder bit for task.

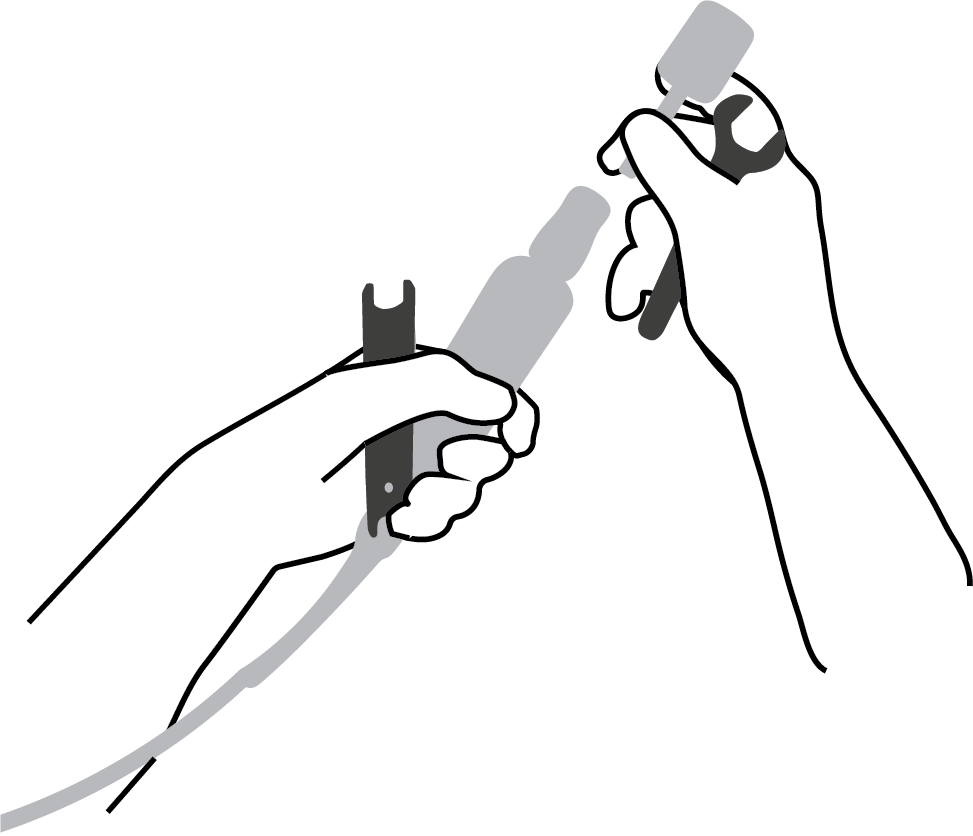

03. Insert bit into collet and tighten.

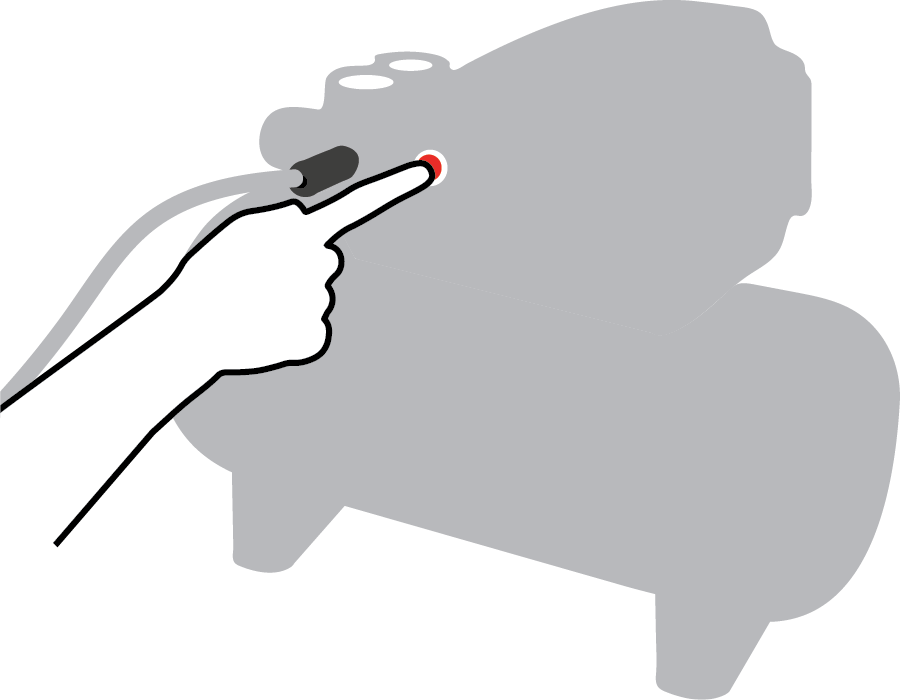

04. Turn on air compressor.

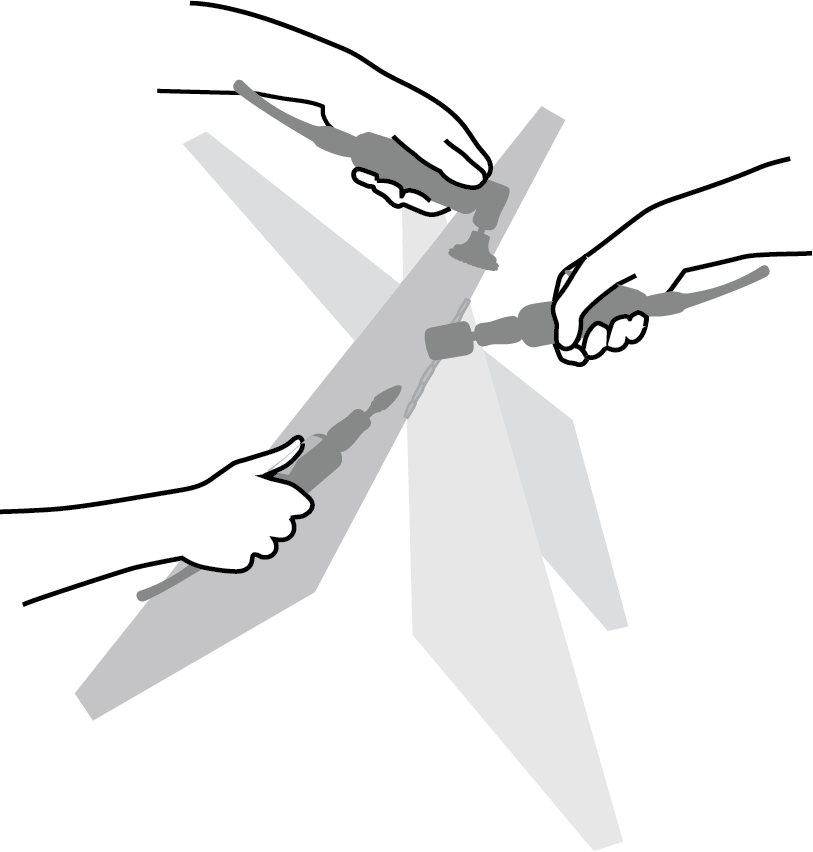

05. Grind down non-flush points.

Issues with manueverability:

When using a die grinder there can be limitations caused by the angle of the tool. While a straight angle grinder can be used for more exterior spaces, occasionally a 90° tool is required to reach more internal areas.

How can I design a die grinder that allows maneuverability between 0° and 90°?

Having to switch between straight and right angled die grinders takes up time and requires the ownership of separate tools. This design will consolidate the functions of the two grinder into one multi-functional tool.

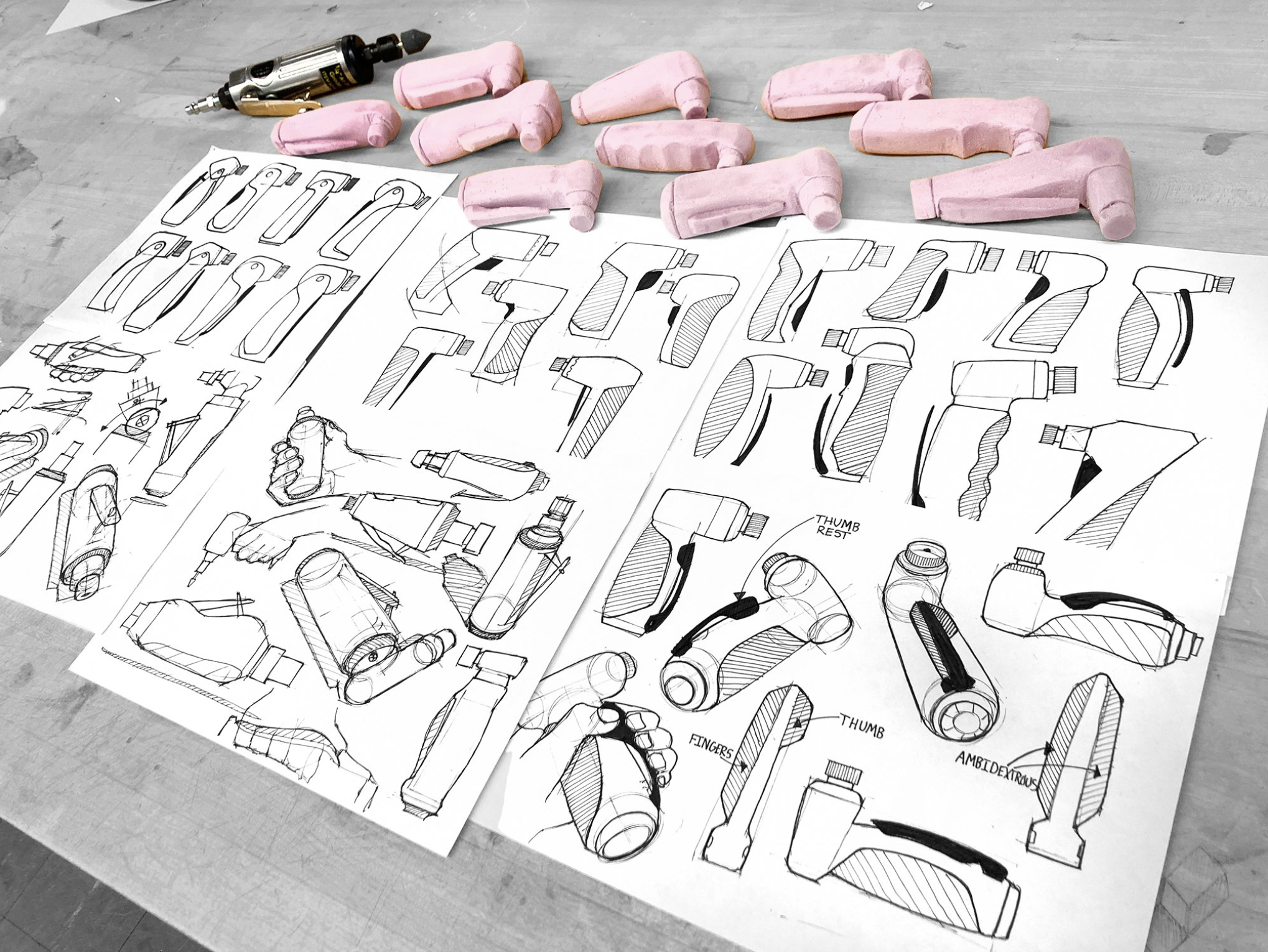

Sketching and form prototyping:

After sketching I explored form through foam and plastic modeling with the use of hand tools, CNC machining, and 3D printers.

Design goals and mechanics:

The goal of the Flex-Grinder is to consolidate workspaces where pneumatic tools/grinders may be used. To accomplish this the tool:

Eliminates the need for several different angled die grinders by creating a range of motion in one tool

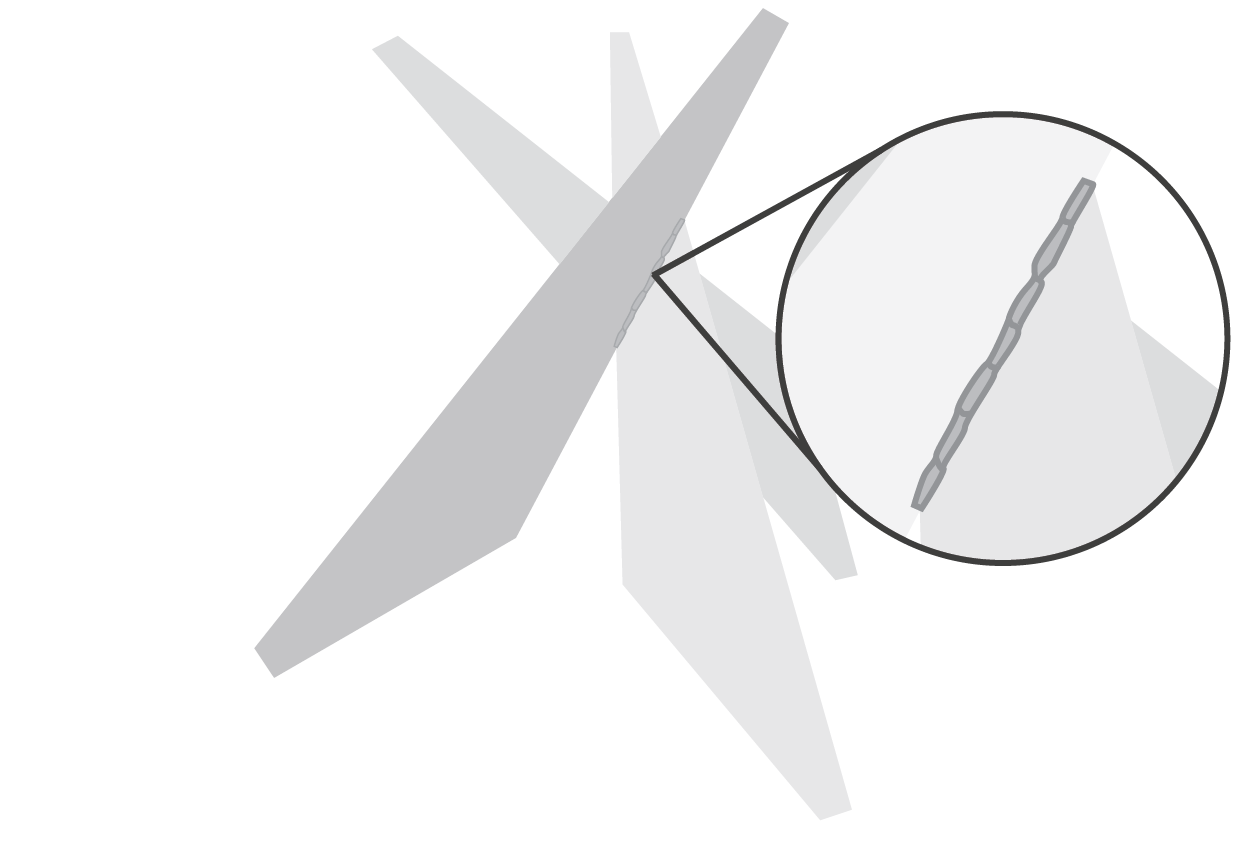

A universal joint allows for translation to any angle between 0° and 90°

Saves the user time and money through quickly being able to change positions without having to detach from the air compressor

Planetary Gears: Increases the restricted RPM caused by the universal joint and allows for the bit to rotate faster.

Universal Joint: Able to translate the axis of motion into any direction within 90 degrees of the joints base.

Ball and Socket Joint: Guides the range of motion easily with a 0 degree to 90 degree axis of movement.